This line can be used to automatically fill 50-5000ml general solution, special solution, dialysis solution, Parenteral nutrition, Antibiotics, Irrigation and Disinfectant solution etc.It can supply you different PP bag design with single boat type port, single/double hard ports, double soft tube ports etc.

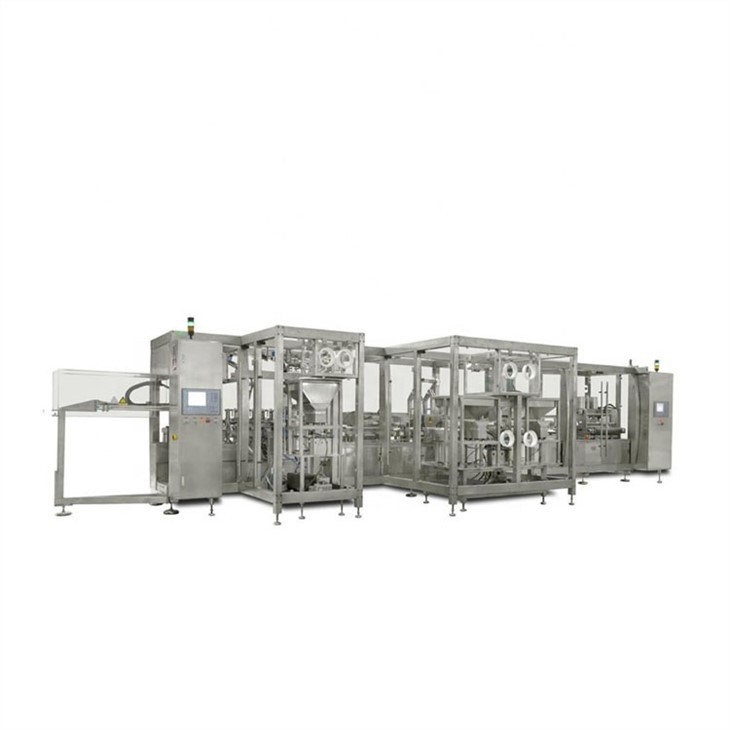

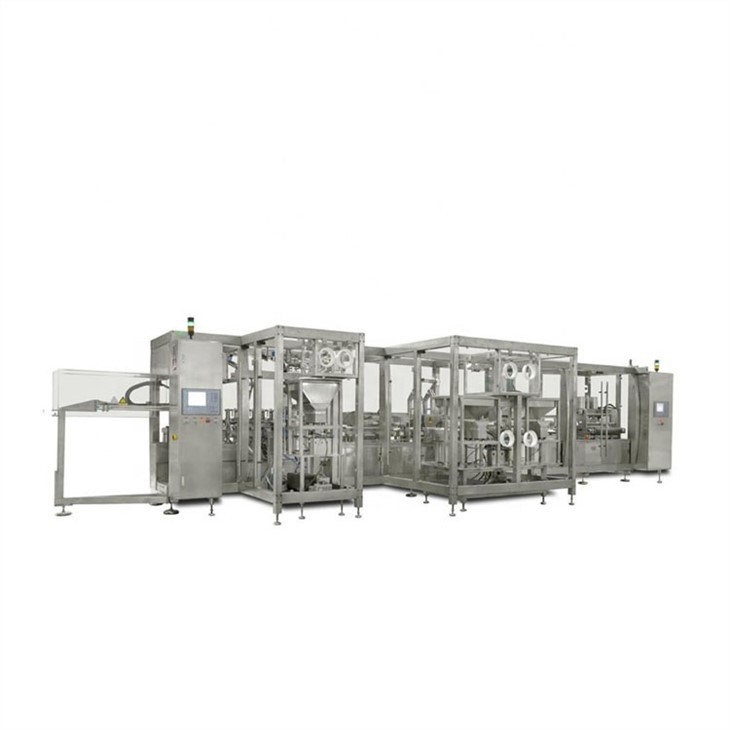

Soft Bag IV Solution Filling Machine

Product Description of Liquid Filling Machine

1.Non-PVC soft bag IV solution production line can automatically finish film feeding, printing, bag making, filling and sealing in one machine.

2.This line can be used to automatically fill 50-5000ml general solution, special solution, dialysis solution, Parenteral nutrition, Antibiotics, Irrigation and Disinfectant solution etc. It can supply you

different PP bag design with single boat type port, single/double hard ports, double soft tube ports etc.

Main ApplicationofLiquid Filling Machine

Used for the automatic filling of 50~5000ml conventional infusion, special infusion, flushing/urination, parenteral nutrients, antibiotic and special medicine.

The automatic Non-PVC Soft Bag IV-solution Production Line, which can realize the integration of bag-making, filling and sealing, is the result of our years of experience and built on the basis of absorption of the same kind of equipment technique from both home and abroad.

This production line is made up of two parts, that is bag-making and filling & sealing, which including the mechanisms of automatic film-sending, words-printing, fashioning, one-time crater tube, two-time

crater tube, bag cooling & separating, port funnel-fixing clip reversing, port funnel sending, port funnel

pre-heating, main transporting, filling pipeline, CIP/SIP system, bag pressuring, cap-sending set, heating set, emptying set, bag coming-out set, bag coming-out track and automatic control, etc.

Machine Parameters of Liquid Filling Machine

Name |

IV Soft bag filling machine |

||

Production capacity |

1200 pcs/hour |

||

Filling nozzles |

1 |

||

Filling accuracy |

1100ml±2%,250ml±1.25%,500ml±0.75%,1000ml±0.5%,2000ml±0.3% |

||

specification |

10-100ml |

||

Bag width form |

120130135年 |

||

Overall dimension: (LxWxH) |

2940x2900x1500mm |

||

Products ShowofLiquid Filling Machine

Feature of Liquid Filling Machine

1.100% film utilization: No waste edge between bags, reducing both material and energy consumption.

2.Special IV bag design: each bag saves 10mm film than others.

3.Reliable heating and welding system: Leakage rate less than 0.03%.

4.Quick changeover: 0.5-1 hour to switch from one size to another.

5.Stable transmission system: only needs 1 control system, 1 HMI and 1 operator.

6.Safe filling nozzle: No solution overflows, no particles generation.

7.Auto faulty rejection system detected by the machine.

8.生产线长度减少了1/3,workshop and air conditioning and cleaning area are reduced by 1/3, greatly reducing the initial investment and future running cost.

9.Simple structure, more stable and reliable performance.

Application ofLiquid Filling Machine

FAQ:

Q1:Are You A Factory or A Trading Company?

A: We Provided Perfect OEM and After-sale Service.

Q2:Where is Your Factory? How Can I Visit Your Factory?

A:Our Factory is Located on HangZhou Zhejiang Province. We Are Warmly Welcom You Visit Our Factory if You Have a Travel Plan.

Q3:Can You Send Me the Video To Show The Machine Works?

A:Certainly, We Have Made Video of Every Machine.

Q4:How Can I Know Your Machine Is Designed For My Product?

A:You Can Send Us Samples of Your Product and We Test It On Machine.

Q5:How Can I Pay My Order?

答:通常我们接受信用证,D / A, D / P、T / T, Western Union, MoneyGram,Cash Paying Methods.

Q6:Do you Have a Ce Certificate?

A:For Every Model of Machine, It Has a CE Certificated.

Q7:What about install?

A. Our engineers will be sent according to your project.However,the customer will pay the economic air tickets round trip and arrange the accommodation for them.